API 5L steel line pipe adopts different steel grades, which are Gr. B, X42, X46, X52, X56, X60, X65, X70, X80. Some manufacturers are capable of manufacturing steel grades up to X100 and X120. As steel line pipes’ grades go higher, they have stricter control on the carbon equivalent control, and higher mechanical strength performance.

Moreover, in the same grade, seamless and welded API 5L pipes have different chemical compositions, namely, welded pipes have stricter requirements and lower amounts of carbon and sulfur.

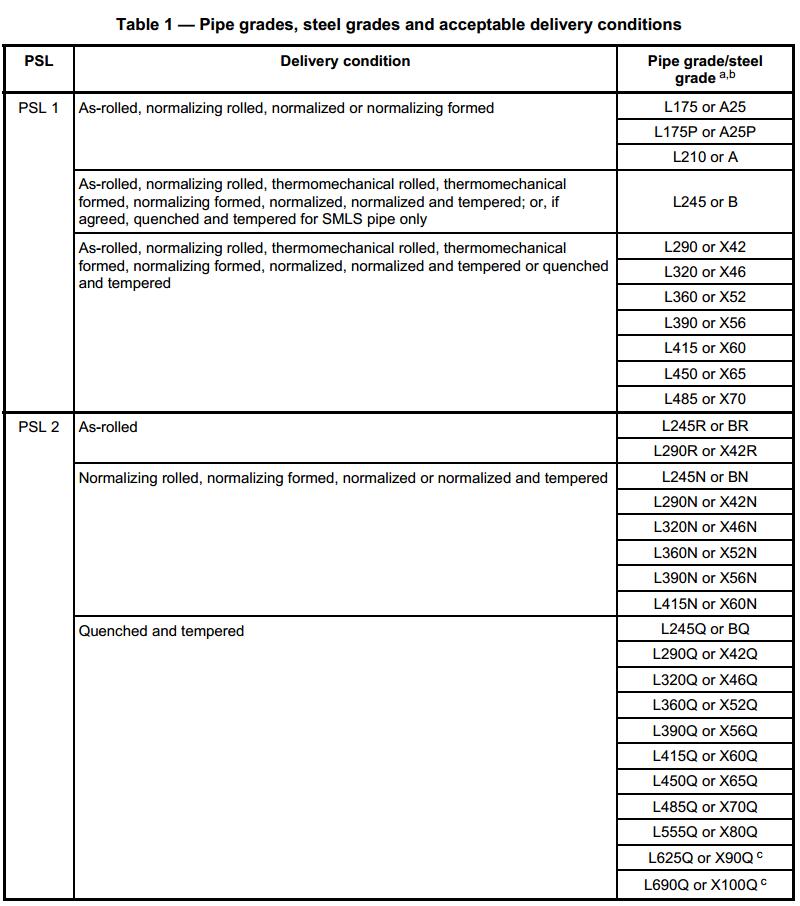

In terms of different delivery conditions, there are also As-rolled, normalizing rolled, thermomechanical rolled, normalizing formed, normalized, normalized and tempered, quenched and tempered.

Delivery Conditions for Each API 5L Grade

more:

For intermediate grades, API 5L pipe grade shall be in one of following description format:

a. The letter L followed by the specified minimum yield strength in Mpa. For example, L290 (X42) means the minimum yield strength is 290 Mpa. In case of PSL2 pipe, Suffix letter (R, N, Q or M) shall be added to describe the delivery condition;

b. The letter X followed by a two or three digital number equal to the minimum yield strength in 1000 psi rounded down to the nearest integer and, for PSL2 pipe, the letter describing the delivery condition (R, N, Q, or M) consist with the above formats.

Letter R: As rolled

Letter N: Normalizing rolled, Normalized formed, Normalized

Letter Q: Tempered and quenched

Letter M: Thermomechanical rolled or thermomechanical formed

Letter S: Sour Services, comes with PSL2 pipe with for NS, QS, MS, eg API 5L X52MS, API 5L X65QS.

Product Specification Level (PSL1 and PSL2 in API 5L)

What is PSL

PSL is the abbreviation of product specification level, which includes PSL1 and PSL2. It also could be deemed as quality level.

PSL1 and PSL2 differences

Please click here for the differences between PSL1 and PSL2 pipes.

Requirement

PSL1 and PSL2 have not only different testing requirements, but also different chemical composition and mechanical properties.

PSL1 has stricter requirements than PSL2 in terms of chemical composition, tensile properties, impact test, nondestructive testing and other indicators.

Impact Test

PSL1 does not require impact test, while it is required for PSL2 (except X80).

Non-destructive Test

PSL1 does not require non-destructive test, while it is required for PSL2.

(NDT: Non-destructive inspection and testing uses radiographic, ultrasonic or other methods (not breaking the material) in API 5L standard, to reveal pipe defects and imperfections.)

API 5L Pipe Data Sheet Specification

API 5L Pipe Data Sheet specification including chemical composition and mechanical properties for PSL1 and PSL2 pipe.

Chemical Composition

Chemical composition for PSL1 line pipe with wall thickness ≤ 25.0 mm (0.984 inch)

API 5L PSL2 Pipe chemical properties:

Chemical Composition for API Sour Pipe

a. If C > 0.12%, CEIIW limits shall be applied; If C ≤ 0.12%, CEPCM shall be applied.

b. For each reduce of 0.01% for maximum C, an increase of 0.05% maximum Mn is permissible, up to a maximum of 0.20%.

c. Al ≤ 0.060%; N ≤ 0.012%; Al/N ≥ 2:1 (titanium-killed or titanium-treated steel not applicable); Cu ≤ 0.35% (Cu ≤ 0.10% if agreed); Ni ≤ 0.30%; Cr ≤ 0.30%; Mo ≤ 0.15%; B ≤ 0.0005%.

d. For seamless and welded pipes, Ca ≤ 0.006%; For welded pipe if Ca is added by intention, unless agreed, Ca/S ≥ 1.5 in case S > 0.0015%.

e. For SMLS pipe maximum limit for S could be increased to ≤ 0.008%, and in case welded if agreed to ≤ 0.006%. For higher S conent in welded pipe, lower Ca/S ratios maybe agreed.

f. Nb + V ≤ 0.06%, unless otherwise agreed.

g. Nb + V + Ti ≤ 0.15%.

h. In case seamless pipe, listed CEPCM value could be increased by 0.03.

i. Mo ≤ 0.35% in case agreed.

j. Cr ≤ 0.45% in case agreed.

k. Cr ≤ 0.45% and Ni ≤ 0.50% in case agreed.

Tensile and Yield strength

For intermediate grades, the difference between the specified minimum tensile strength and minimum yield strength for the pipe body shall be as given in the table for the next higher grade. The specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body ung footnote a)

a. For intermediate grades, the difference between specified maximum yield strength and minimum YS shall be as given in the table for the next higher grade, and the difference between specified minimum tensile strength and the specified minimum TS shall be as given in the table for the next higher grade. For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000 psi). For intermediate grades greater than Grade L320 or X46 and lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psi).For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units, the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

b. For grades > L625 or X90, Rp0,2 applies.

c. Above limit applies for pipe with D > 323,9 mm (12.750 in).

d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using footnote a).

e. For pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 495 MPa (71 800 psi).

f. The specified minimum elongation, Af, shall be as determined with following equation:

g. Lower values of Rt0,5/Rm may be specified by agreement.

h. For grades > L625 or X90, Rp0,2 /Rm applies. Lower values of Rp0,2 /Rm may be specified by agreement.

Mechanical Properties for API 5L Sour Service Pipe

The strength value is the same as PSL2.

API 5L Line Pipe Test Methods

Hydrostatic Test

a. Jointers need not be hydrostatically level, provided that the portions of pipe used in making the jointers were successfully hydrostatically tested prior to the joining operation.

b. Except in the previous situation, the pipe shall withstand the hydrostatic test without leakage through the weld seam or the pipe body.

Bend test

Cracks should not occur in any part of the sample and opening of weld shall not occur as well.

Please Note: For all bend test, the weld extends to 6.4 mm (0.25 in) on each side of fusion line.

Flattening Test

The flattening test method is used to verify the deformation performance of line pipe to the specified size and display its defects. According to the stress and deformation characteristics of the specimen during the flattening process, the flattening test shall show the resistance to longitudinal cracking and circumferential cracking of the pipe and display its internal defects and surface defects.

Other than the above three common tests, there are other tests that are required in each circumstance.

Guided-bend test

CVN impact test for PSL2 pipe (including pipe body tests, pipe weld and HAZ tests)

DWT test for PSL2 welded pipe

Surface Conditions, Imperfections and Defects Appearances

All API 5L pipes shall be free from defects, cracks, sweats and leaks.

More defects as:

Undercuts in SAW and COW pipes.

Arc burns

Laminations

Geometric deviations

Hard spots

Other surface imperfections (Defects depth more than 0.125 thickness or ≤ 0.125 wall thickness refers to Clauses C in API 5L.)

API 5L Pipe Sizes and Tolerances

Tolerances for diameter and out of roundness

Tolerances for wall thickness

Tolerances for pipe lengths

API 5L pipe length tolerances shall be complied as following conditions:

a. Random length shall be delivered as below table 12.

b. Approximate lengths shall be delivered as tolerances of +/- 500 mm.

Order Information for API 5L pipe

a. Quantity in meters or in tons. Total meters or total pieces.

b. PSL1 or PSL2 (N/M/Q/NS/MS/QS), Sour Services, Onshore/Offshore

c. Pipe Types (Seamless or welded, EW, ERW, HFW, SAW, LSAW, HSAW, SSAW)

d. Reference documents to API 5L.

e. Steel Grade

f. OD (Outside diameter) and WT (pipe wall thickness)

g: Length and length type (Double random length / Single random length / Fixed length / Approximate length)

h. Individual annexes applicability of confirmation

Additional Information

The following additional information could also be included in the PO in different situations.

• Pipe designation

• Chemical composition for intermediate grades

• Carbon equivalent limits

• Diameter or round tolerances for special size pipe

• Jointer welds

• Ends type

• Repairs requirements

• CVN impact test

• DWT test

• Hardness test

• Pipe markings and end colors

Etc.